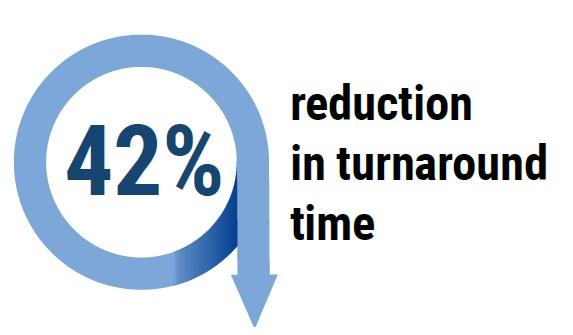

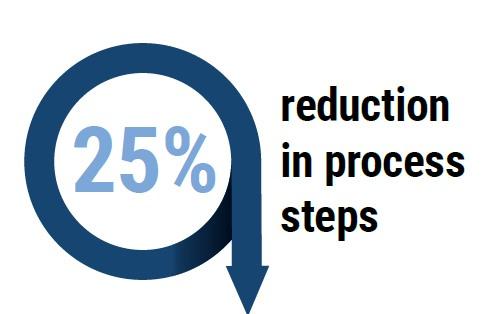

Gastroenterology Laboratory Reduces TAT 42% by Eliminating 25% of Touch Points

A growing gastroenterology group is looking to double the number of clinics within its network by the end of 2019. To meet their goal, they will need to change their current processes to maintain their high standards of quality without negatively impacting their turn-around-time.

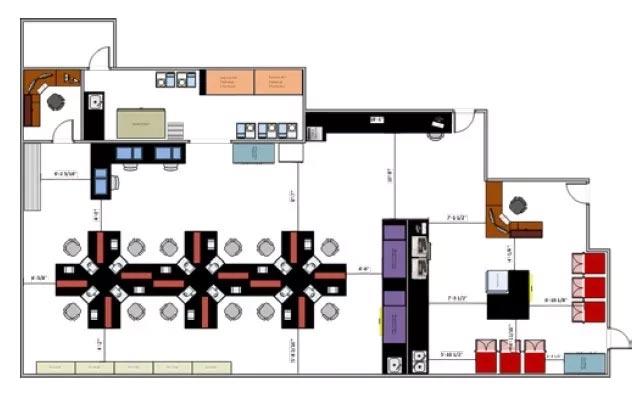

The Leica Biosystems Process and Solutions Optimization team partnered with this customer to optimize their processes to enable them to incorporate anticipated volume growth. The first step involved observing and mapping their current processes. By mapping their current processes and including time measures, it became apparent that the staff was experiencing large wait times in two areas – receiving patient samples at the lab and tissue processing. Patient samples were delivered to a lock box by 8:00 PM each night and would sit until 7:00 AM the following morning before being received (an 11- hour wait time). Although grossed cassettes were ready for tissue processing by 6:00 PM each night, they would be placed in a delayed overnight run to start at 2:00 AM (an 8-hour wait time).

Due to the growing volume, the lab was planning to hire additional staff. The Leica Biosystems Process and Solutions Optimization team worked with lab management to extend the current staffing schedule. By extending the hours that the lab is staffed each day, the two identified wait times could be addressed. By moving the time of day that patient samples are received, accessioned, and grossed, the lab reduced turn-around-time (TAT) by 42%. Another benefit of extending staffing into off hours is equipment could be shared, reducing the need for additional capital expenditure.

Another issue that was identified through the process map was the number of touch points within the accessioning through gross dictation processes. The current processes require 4 separate distinct touch points that include 16 process steps. The changes result in only 2 separate and distinct touch points and a 25% reduction to 12 process steps.

Through these two changes, this facility will be in a great position to handle the increased workload, at the same time realizing a reduction in TAT and ultimately benefiting its patients.

Projections and Realized Results are specific to the institution where they were obtained and may not reflect the results achievable at other institutions.

Want to see how the Leica Process and Solutions Optimization team can help improve your lab's workflow?

Related Content

Leica Biosystems content is subject to the Leica Biosystems website terms of use, available at: Legal Notice. The content, including webinars, training presentations and related materials is intended to provide general information regarding particular subjects of interest to health care professionals and is not intended to be, and should not be construed as, medical, regulatory or legal advice. The views and opinions expressed in any third-party content reflect the personal views and opinions of the speaker(s)/author(s) and do not necessarily represent or reflect the views or opinions of Leica Biosystems, its employees or agents. Any links contained in the content which provides access to third party resources or content is provided for convenience only.

For the use of any product, the applicable product documentation, including information guides, inserts and operation manuals should be consulted.

Copyright © 2025 Leica Biosystems division of Leica Microsystems, Inc. and its Leica Biosystems affiliates. All rights reserved. LEICA and the Leica Logo are registered trademarks of Leica Microsystems IR GmbH.