Leica Biosystems RM2245

| This Item has been discontinued | |

| Replaced by HistoCore MULTICUT | |

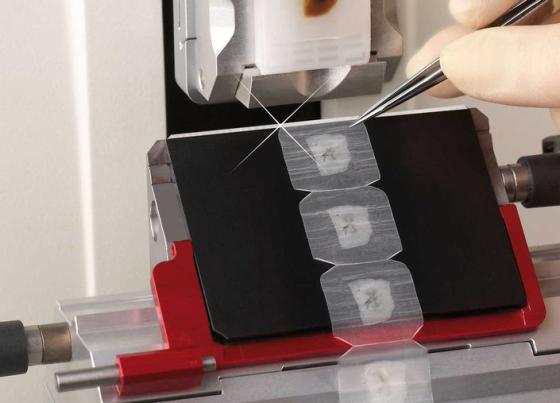

Semi-Automated Rotary Microtome

The RM2245 is a semi-motorized rotary microtome, designed for routine in histopathology.

Manual sectioning is enhanced by a high-precision motorized specimen feed, which results in efficient operation with maximum section quality and reproducibility.

Choose between conventional, full-hand-wheel rotation, manual sectioning or "rocking mode", where the hand-wheel is turned back and forth over a short distance. The instrument has been specially designed for the experienced user who prefers manual over motorized sectioning and meets the many requirements of modern laboratories.

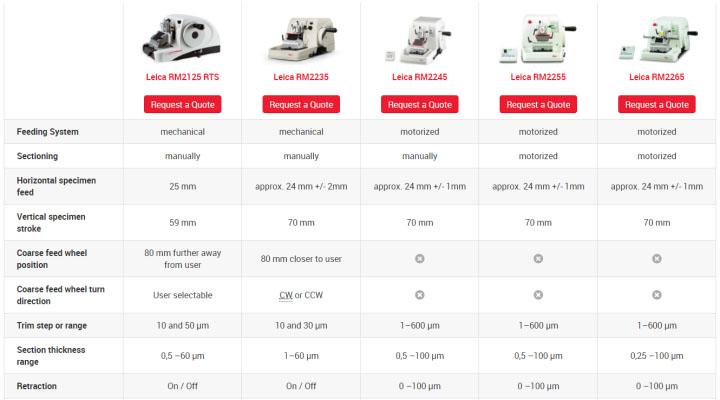

Specification

Brochure

Certificate

SDS

IFU

Frequently Asked Questions

- Advantages in the application of disposable blades over conventional knives:

- Substantial cost reduction

- Consistent section reproducibility

- Consistent section quality

- Support of all common microtome systems

- For all paraffin embedded samples

- For all cryosectioning applications

- Expensive resharpening no longer required

- No longer dependent on quality of selected resharpening service

- No downtime while knives are at the resharpening service - Standard re-usable steel knives and disposable blades in comparison with standard microtome blades: In typical histology laboratories, 50-100 blocks on average per day and person will be handled. Depending on the type of specimen and the way of trimming, up to 50 specimens and more can be worked on. Assuming the laboratory is handling all the different types of tissues that are typically processed in a histopathologyl lab, up to 20 blocks can be cut with high quality microtome blades retaining the same sectioning quality.

- Conventional steel knife 16 cm c-profile: As a rule, no more than 80 to 100 blocks will be cut by a steel knife with consistent section quality. Thereafter, the steel knife has to be sharpened regularly to regain the required knife performance. Due to the design of microtome knife holders, only 70% to 80% of the total knife edge can be utilized for cutting. The remaining 20% to 30% are not accessible because of the clamping principle commonly used.

Spring balance system is not calibrated: Set the hand-wheel to the 3 o'clock position and let it sit. If the wheel drifts upward or downward then the spring system is not balanced and requires adjustment. If the hand-wheel does not drift, then no adjustment is necessary. If adjustment is necessary, the user can balance the unit by adjusting a flathead screw, which is accessible through the hole on the underside of the microtome base plate. Removal of the section waste tray is necessary. If the specimen head slightly rises, turn the screw counter-clockwise completing 2 or 3 full rotations.

- Check the specimen advance (micrometer) setting to be certain that it is set correctly.

- Activate the coarse specimen advance to confirm that the specimen head is advancing.

- Select trim setting (e.g. 20µm) and try sectioning.

- Check that the knife holder is firmly clamped.

- If all the above fail – call Technical Service.

- Linear bearings have moved in cage and are at their lower limits: Linear bearings need to be cleaned, exchanged, possibly re-greased.

- Alignment of bearing cage is incorrect: Open a service call.

- Retraction "ON" causes louder clunking sound: Turn the retraction off by turning flathead in back of the microtome.

Testimonials

"Bronson Methodist Hospital: a systematic approach to validating xylene‑free processing"

Leica PELORIS improving workflow, safety, and productivity

Excellent results with Leica PELORIS xylene-free processing

Going green with a next generation tissue processor