Increasing Routine Staining Productivity & Throughput Through Automation

The Leica Biosystems Process and Solutions Optimization team has partnered with a large province-based hospital to review the impact of automating their Routine Staining area. This hospital is most interested in the benefits they could realize in reducing their current hands-on intensive process and improving the throughput of their H&E staining.

During the Optimization Assessment, the Process and Solutions Optimization team observed the current processes involved in routine staining over several days. The team was able to benchmark the current processing time and number of steps involved.

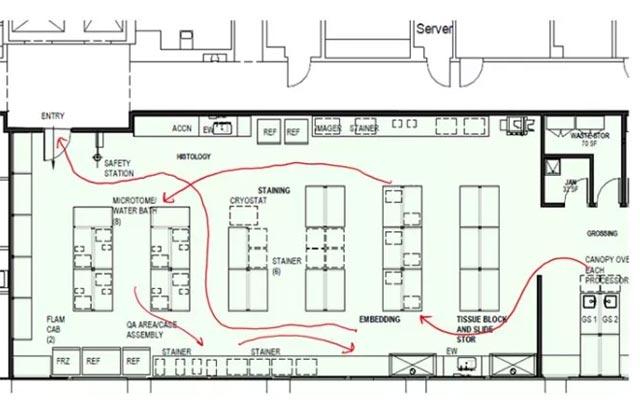

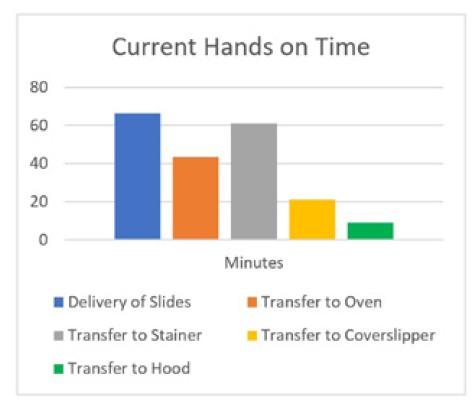

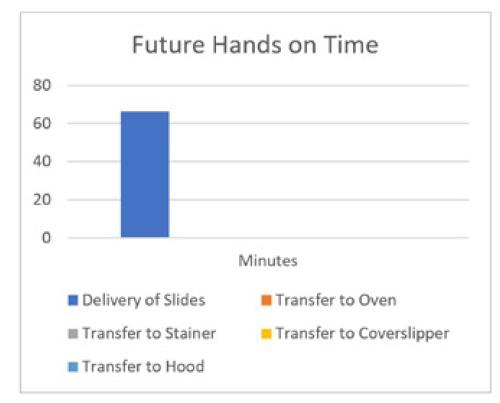

It was observed that the staff is required to transfer the racks of slides through several steps in their process mainly due to the older instrumentation being used to perform routine staining. As a result, the workflow has been designed to transfer racks of slides to and from the oven, to and from the stainer, to and from the coverslipper, and to and from a vented hood for slide drying. Due to the high amount of hands-on time required, the lab only operates the routine staining for 10 hours each day.

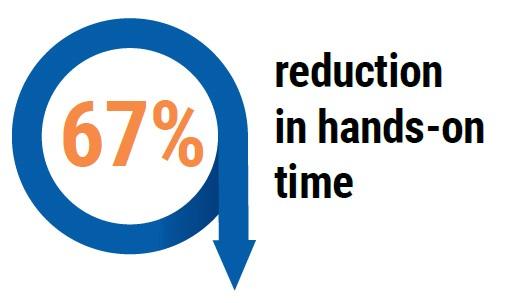

Through Analyzing the data, the Process and Solutions Optimization team was able to show that by replacing the current Leica ST4040 Linear Staining System with detached coverslippers with two HistoCore SPECTRA Workstations, this academic medical facility could realize a 45.4% reduction in hands-on time. Further analysis showed that by modifying their current workflow, another 21.6% reduction could be achieved.

By combining integrated solutions and optimizing efficiencies, this facility could reach an overall 67% reduction of hands-on time for routine staining. Because of the reduction of hands-on time required, they could increase the hours of operation of routine staining to 16 hours each day, which is the total number of staffed hours for the laboratory. These changes would help increase the laboratory’s capacity and reduce their turn-around-time for delivering slides to their Pathologists.

Projections and Realized Results are specific to the institution where they were obtained and may not reflect the results achievable at other institutions.

Want to see how the Leica Process and Solutions Optimization team can help improve your lab's workflow?

Related Content

El contenido de Leica Biosystems Knowledge Pathway está sujeto a las condiciones de uso del sitio web de Leica Biosystems, disponibles en: Aviso legal.. El contenido, incluidos los webinars o seminarios web, los recursos de formación y los materiales relacionados, está destinado a proporcionar información general sobre temas concretos de interés para los profesionales de la salud y no está destinado a ser, ni debe interpretarse como asesoramiento médico, normativo o jurídico. Los puntos de vista y opiniones expresados en cualquier contenido de terceros reflejan los puntos de vista y opiniones personales de los ponentes/autores y no representan ni reflejan necesariamente los puntos de vista ni opiniones de Leica Biosystems, sus empleados o sus agentes. Cualquier enlace incluido en el contenido que proporcione acceso a recursos o contenido de terceros se proporciona únicamente por comodidad.

Para el uso de cualquier producto, debe consultarse la documentación correspondiente del producto, incluidas las guías de información, los prospectos y los manuales de funcionamiento.

Copyright © 2025 Leica Biosystems division of Leica Microsystems, Inc. and its Leica Biosystems affiliates. All rights reserved. LEICA and the Leica Logo are registered trademarks of Leica Microsystems IR GmbH.