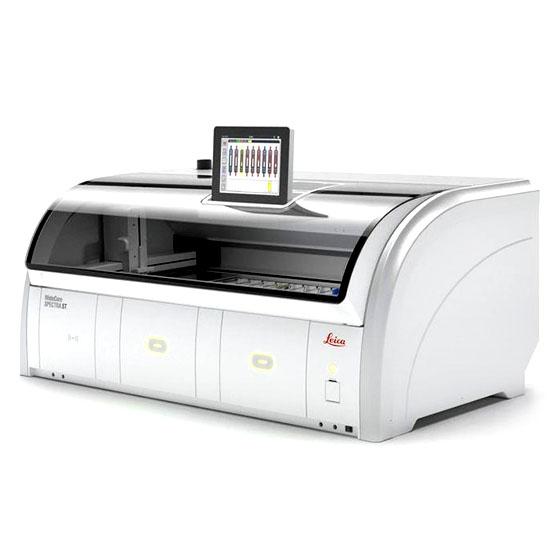

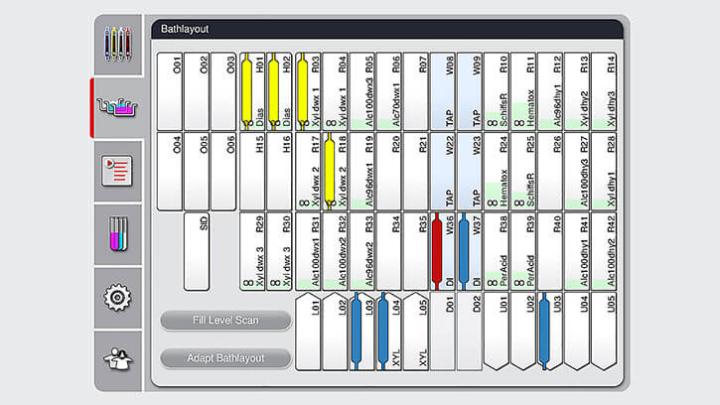

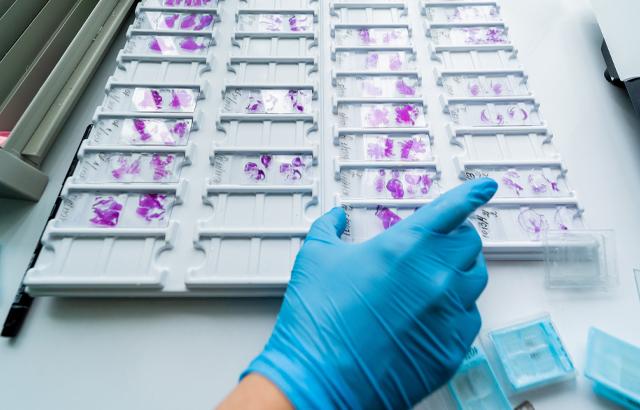

Precise Reagent Management and Cost Control with Single Slide Counting

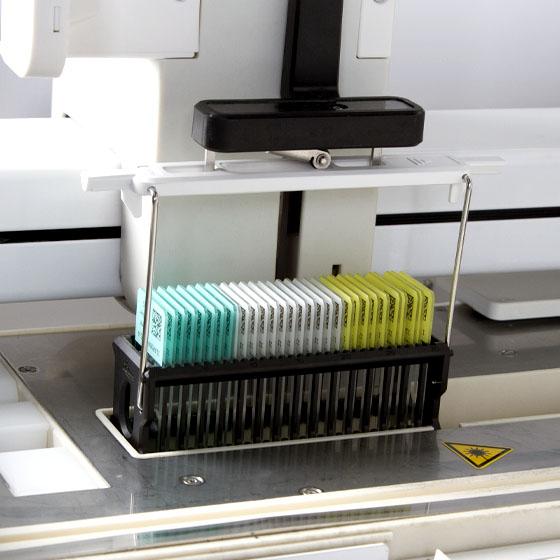

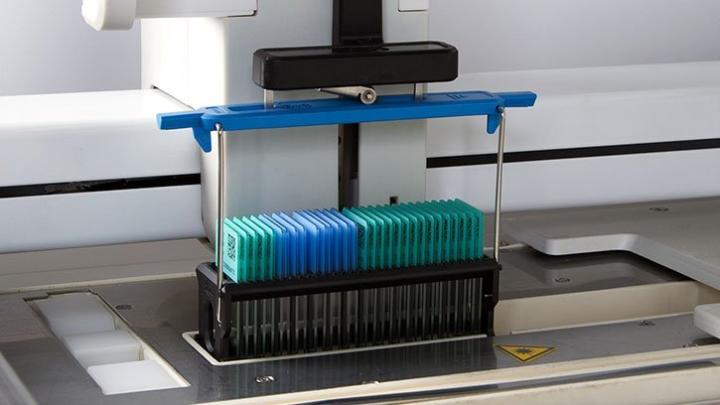

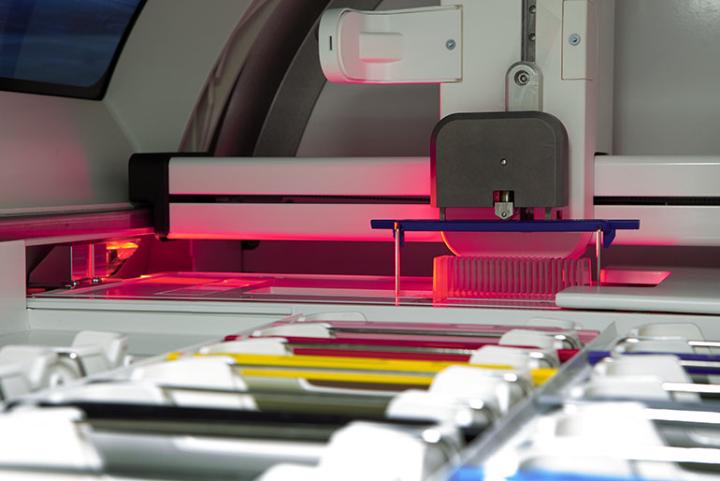

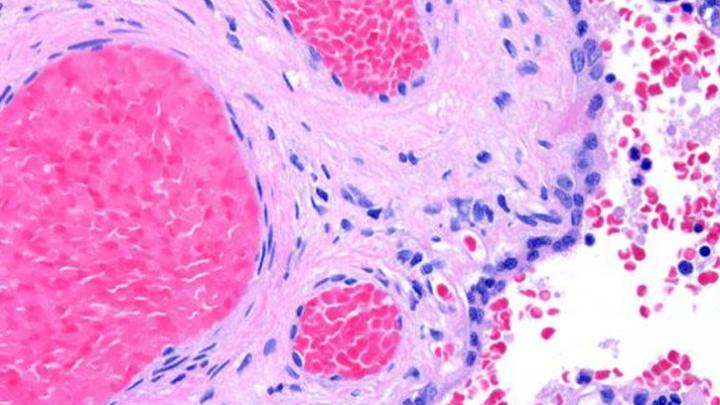

Have precise control over reagent conditions, and coordinate reagent exchange using RFID-monitored consumables, color-coded rack technology, and a slide counter. Together, these features minimize user errors, save time, control costs, and reduce waste in the lab.